Circular Retrofit Lab

Full renovation of prefabricated student housing modules for multiple uses

Follow the development of CRL in the Pilot Project Blog.

th, td { padding: 10px;}

Focus |

|

Type |

|

Size |

|

Function |

|

Location |

|

PILOT SUMMARY

The pilot project tested and implemented different scenarios for the reuse and refurbishment of the VUB Campus’ prefabricated student housing, without generating a large amount of waste. Strategies have been explored for internal transformations, external transformations, and the module’s multiple functional reconfigurations.

Depending on their expected rate of change in the floor plan, three different types of walls were defined, analysed, constructed and transformed: walls with (1) a high rate of change, (2) a high degree of flexibility for the integration of technical infrastructure and 3) a low rate of change.

Place

Vrije Universiteit, Pleinlaan 2, 1050 Brussels

Contact

Anne Paduart, VUB: anne.paduart@vub.be

Presentations

Posters SBE19 Brussels – BAMB-CIRCPATH, February 2019 (pdf 8 MB)

Circular Retrofit Lab – Presentations and visits to BAMB Pilot Projects 13 October 2017

Reports

OBJECTIVES

The circular refurbishment tested dismountable, adaptable and reusable solutions for maximizing waste reduction. The pilot developed a co-creative process all along the (re) design, (re) build, (re)use, repurpose or dismantling phases. This necessitated a close collaboration with all the value network stakeholders and future users in the early development phase.

The university organised several round tables with industry stakeholders where design solutions were debated and improved, as well as hands-on workshops with students where solutions were tested.

INNOVATION

The CRL pilot project applied a step-by-step innovation strategy based on products available on the market. This strategy thus incrementally improves products that are

already technically and commercially viable.

Selected products, such as partition walls, had a high initial potential to reach circularity objectives. Together with the manufacturers, the team sought to add new product

capabilities, such as new functionality (ex. from a facility partition wall to a living room separation), reversible connections, etc.

ACHIEVEMENTS

The reversible solutions for internal walls and façades have been integrated in the CRL lab by January 2019. The use of modular, prefabricated and kit-of-parts design approach not

only fostered flexibility in assembly and efficiency in manufacturing but allowed scalling up the implementation. In this respect, the team together with the industry partners implemented efficient operational solutions, such as the use of dry, robust and reversible technical solutions and the use of materials able to endure multiple reuses without being damaged.

REPLICABILITY AND SCALABILITY

CRL is likely to serve as a circular renovation model for the other student housing modules located on the VUB campus. The team paid a special attention to the needs of potential users. In this respect, the project reflects on potential business models able to cope with the evolution of the users’ requirements, thus enhancing the reproducibility and perpetuity of a flexible model.

Opportunities

The development of the Circular Retrofit Lab as an experimental lab for innovative reversible and reusable building solutions creates new opportunities for collaborations between the academic sector, the research sector and private partners.

These collaborations are an added value to the pilot’s objectives and ambitions. The expertise of private partners of the construction sector enabled to set larger goals and to integrate findings from the current building sector. The contact and collaboration with industrial partners also exposed new unknown reversible building systems and new opportunities.

Several product manufacturers and suppliers have already confirmed their participation to the project.

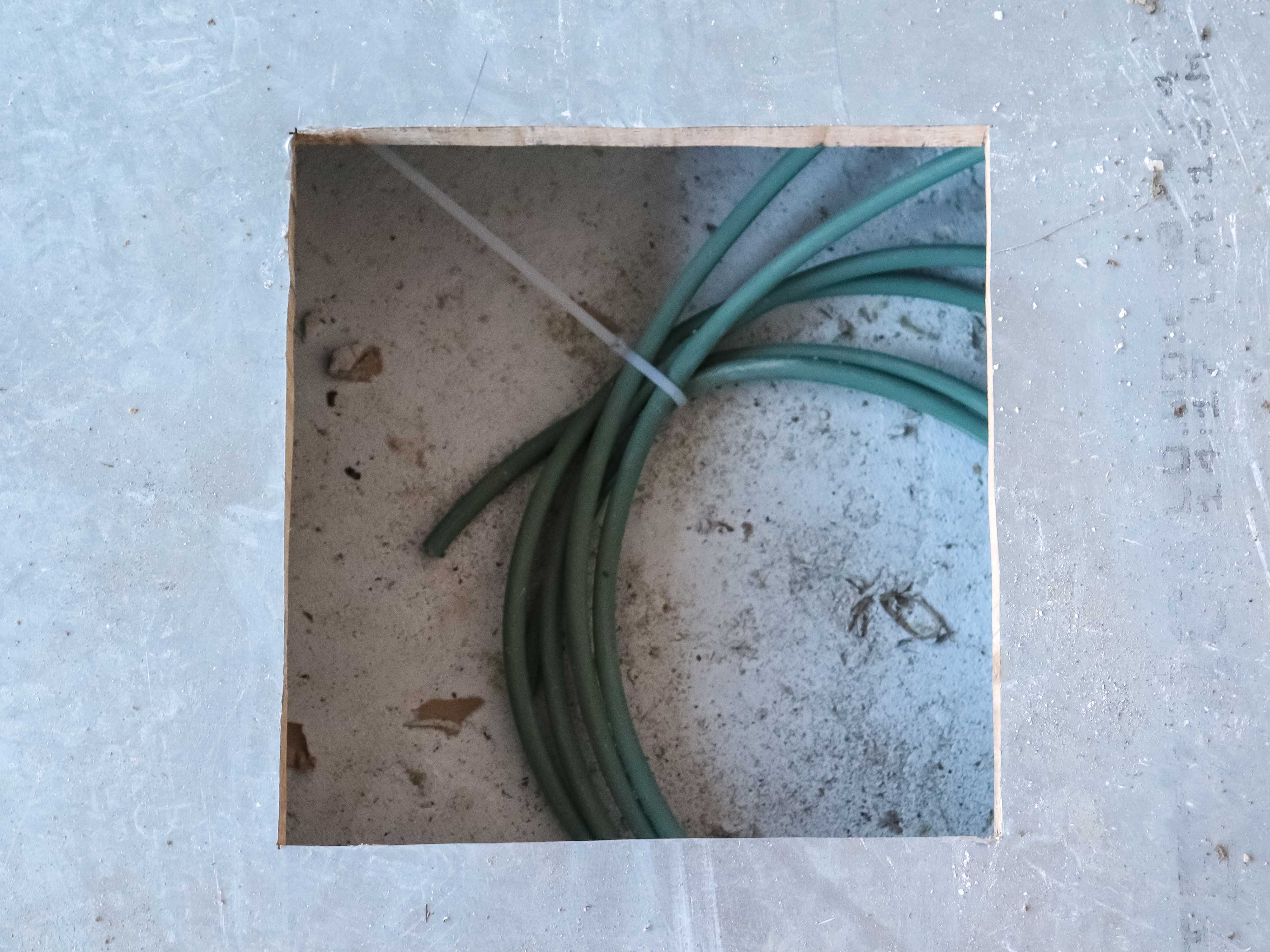

Image: The loadbearing structure

Business models and Circular Retrofit Lab

A building team has been set up for the construction of the Circular Retrofit Lab consisting of the VUB, Kaderstudio and Groep Van Roey.

Groep Van Roey joined as a part of the sounding board group in relation to the circular business models that can be developed based on the BAMB project’s results. In this context, VUB, VITO and Groep Van Roey are investigating if new circular business models can be developed based on reversible design principles. Therefore, two cases are analyzed: one where the building is owned as infrastructure, the other where the building is owned as investment.

The Circular Retrofit Lab – owned by the VUB – is selected for the development of the first case. The financial impact will be evaluated of transformability in building valuation and throughout the total building life cycle. Therefore, the initial investment (design and build), operation and maintenance (think of flexibility), and disassembly/transformation are taken into account from the point of view of different stakeholder groups (owner/investor, user/renter, supplier, facility manager). Hence, reversible building solutions for e.g. wall partitions, can be developed in the future with a larger application in mind, namely as a building systems that can be interchanged over the total university campus.

Click here to find out more about Business Models

The process – Slideshow